Worried about sudden production downtime caused by equipment failure?

- Unexpected equipment failure causing sudden line stoppage…

- Want to understand equipment health status and remaining lifespan

- Unable to identify the cause of failure, leading to prolonged repair time

- Want to improve product quality and increase productivity!

Predict failures and perform maintenance in advance with our Smart Equipment Diagnosis System (PHM)

Our PHM system predicts equipment failures and anomalies, diagnoses the operating conditions, ensures smooth production, and minimizes downtime losses. It also offers automatic inspections and lifespan predictions, helping you manage equipment and maintenance costs effortlessly.

-

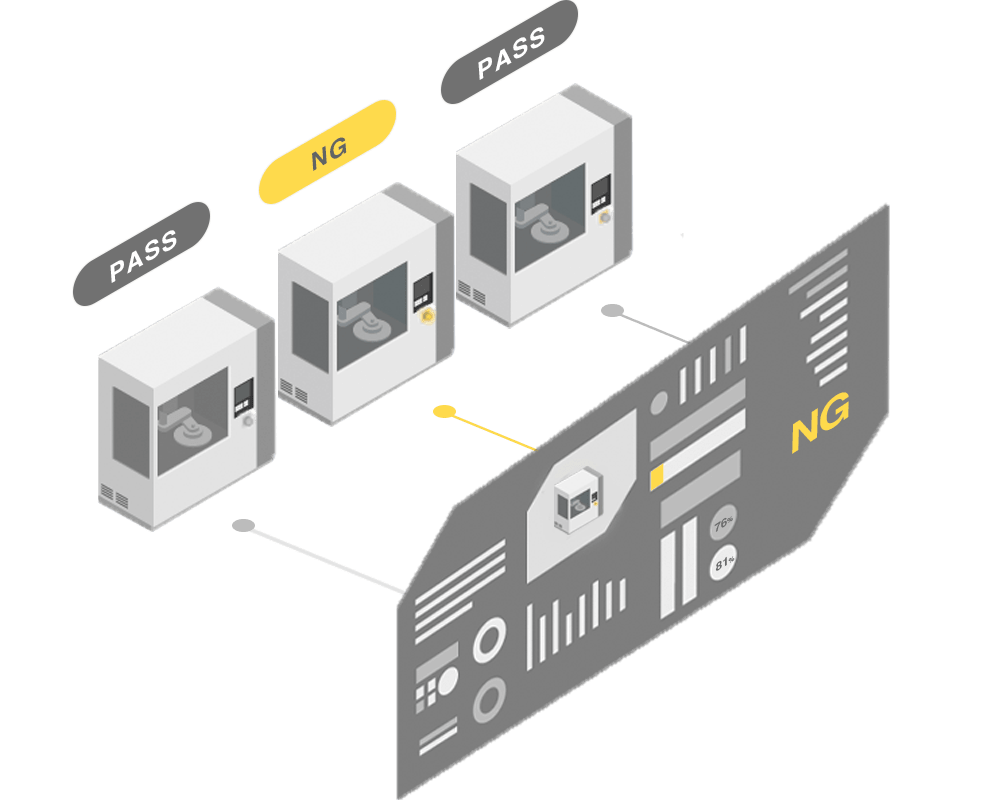

Real-time Monitoring

Immediate AlertsMonitor equipment in real-time and get automatic alerts when anomalies occur. Easy-to-understand data waveforms and indexes help speed up maintenance time. -

Automatic Inspections

Reduced Manual WorkBuilt-in automatic inspection system including maintenance history and scheduling. Manage information and logistics efficiently, reducing human error and labor. -

Remote Expert Support

Communicate with remote experts via head-mounted devices and perform maintenance as instructed without waiting for onsite personnel, significantly reducing downtime.

Application Scenarios

-

Failure Prediction

Prevent Sudden Downtime -

Lifespan Diagnosis

Manage Equipment Costs -

Failure Identification

Shorten Maintenance Time -

Automatic Inspection

Ease Management Work

Solution Details

-

01 Equipment Monitoring and Maintenance

Diagnosis Decision ModuleSpecifically designed for industrial equipment, this AI-based diagnosis module monitors machine health and detects abnormalities using MTQQ communication for real-time alerts. Also features health indexes and automatic maintenance scheduling.

-

02 Remote Expert Collaboration

Using mixed reality technology, engineers can see technical documents and images shared by remote experts through wearable devices, quickly performing inspections and repairs without waiting for onsite support, saving time and manpower.

-

03 Semiconductor Vacuum Pump Diagnosis (DPDS)

Vacuum pumps in smart semiconductor factories often suffer from motor overload leading to unexpected shutdowns. Our DPDS system uses AI algorithms to transform key parameters into intuitive status indicators, enabling engineers to predict failures with 97% accuracy and perform timely maintenance.

-

04 Smart Inspection Devices

・Smart Meter Reading System

Automatically records visualized meter readings and issues alerts, eliminating manual monitoring and recording.

・Flexible MEMS Pressure Sensor

Shows a linear response to varying pressure levels, with higher conductivity under greater pressure. Integrating innovative microstructures and engineering design, it enhances product diversity and enriches the user experience.